SANWA’s History

Our burning passion for manufacturing is something that has never changed since the company was founded. Throughout SANWA’s history we have continued to work on challenges with the consistent feeling of never giving up.

The parent company that formed SANWAHara Nameplate Factory

SANWA’s history overlaps the history of Hara Nameplate Factory, which is our parent company. Hara Nameplate Factory started by Hiroyoshi Hara, the father of Tsutomu Goto our company’s founder, began in 1939 as a company that manufactured nameplates listing such things as the performance and manufacturing company for aircraft machinery and motors. After World War II, the company shifted its focus to manufacturing nameplates for industrial machinery instead of aircraft while growing steadily as a company specializing in the manufacture of metal nameplates. Tsutomu Goto supported his older brother Hiromori Hara, who followed in his father’s footstep to become the company president, and contributed to grow the business through sales.

Inside the Hara Nameplate Factory circa 1960

Founding Period

Creating Opportunity from the Changing Times

In 1979, Tsutomu Goto established Sanwa Screen Co., Ltd. as a company that manufactures resin nameplates mainly using silk screen printing. Along with his wife Hideko and her younger brother Seiji Hayashi, Tsutomu Goto succeeded in working through the founding period, in which the company did not yet have any clear goals, to eventually start moving into the business of acrylic display panels for drinking water vending machines. Vending machines experienced explosive expansion through the years of booming postwar economic growth and development competition in the market intensified each year. SANWA was able to catch the waves to significantly extend its business performance.

Left: President Tsutomu Goto in the office Center: Hideko at work Right: Seiji Hayashi

Semi-automatic silk screen printer at the time

The very first ordered acrylic nameplate for drinking water vending machines

Display buttons for vending machines manufactured during the founding period

Growth Period

Expanding Our Business Area, From Home Appliances to Cars

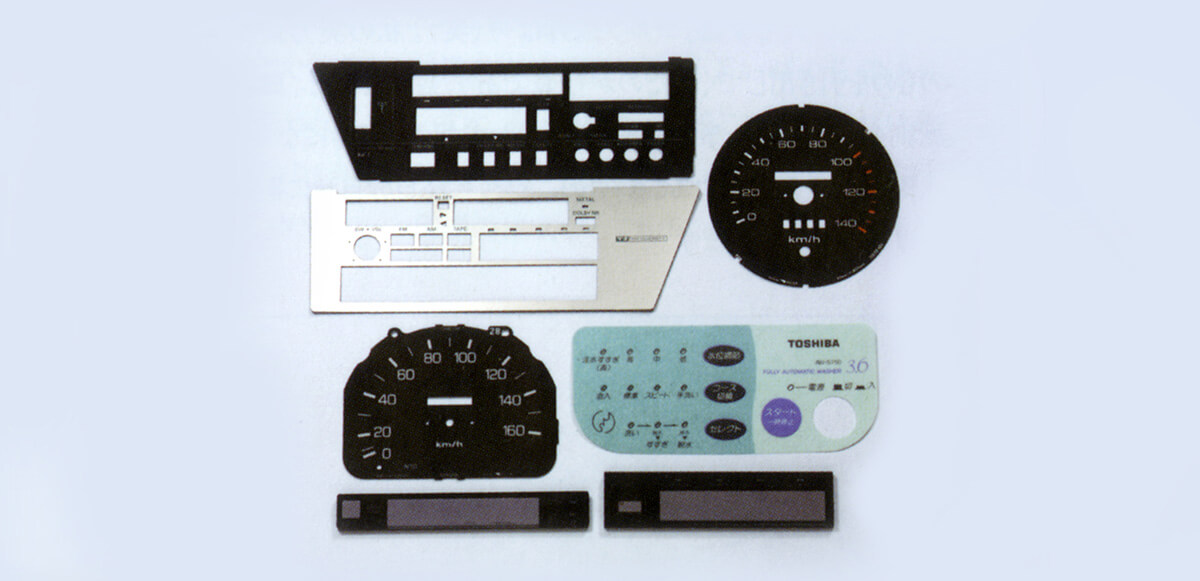

After starting with display panels for vending machines, SANWA also started to produce resin nameplates for home appliances such as rice cookers, microwave ovens, and washing machines. The entire company came together to meet the demanding needs of our customers, and while doing so, its technical capability soundly grew. During the 1980s, the company entered the automotive industry and found success with hot stamp technology, which gives a metallic effect to the surface of resin material. This dramatically increased our sales in the area of automotive parts. We also received orders from a global AV equipment manufacturer, and the size of our business suddenly expanded. Our corporate culture, which boldly takes up the challenge of working on difficult projects that our competitors cannot handle, has become the driving force to gain customer trust and acquire new technology.

Top left: Car display panels Top right: Instrument panel Center right: Washing machine panel Bottom: Audio display panels

1979 |

May |

|

|---|---|---|

1979 Second Oil Crisis |

||

1980 |

May |

|

| Jul. |

|

|

| Dec. |

|

|

1980 The number of produced Japanese passenger cars became the highest in the world |

||

1982 |

Apr. |

|

1983 |

Feb. |

|

| Mar. |

|

|

| Apr. |

|

|

1983 Tokyo Disney Land opens |

||

1984 |

Jan. |

|

| Nov. |

|

|

1985 |

May |

|

| Aug. |

|

|

1986 to 1991 The Heisei boom, bubble economy |

||

1987 |

Mar. |

|

| May |

|

|

| Sep. |

|

|

1987 Launch of the first Japanese car equipped with airbag system 1989 Death of Emperor Showa, Heisei Era started with consumption tax revision (3%) |

||

1990 |

Nov. |

|

1992 |

Mar. |

|

1993 |

Oct. |

|

Development Period

Establishing a Brand with Our Core Technologies

While continuing to be proactive and take up the challenge of meeting difficult orders, SANWA brings together its technical capabilities developed to date, and starts working on a new method referred to as film insert molding. Film insert molding technology, which can support three dimensional shapes and of course flat shapes, is the result of a number of SANWA’s unique developments and has grown into our core technology. Later, we also established two-color molding, and this has significantly contributed towards company growth and strengthening our brand.

Top right: Rice cooker switch panel Top left: Washing machine lid

Bottom left: Washing machine switch panel

Using Technical Capabilities Trusted Throughout the World

In 1994, 15 years after being founded, SANWA set up its first overseas site in Malaysia. This was around the time when Japanese companies started in succession to expand into Asia. Competitors in the same industry from both the Kanto and Kansai regions had already established their presence overseas, and this was a time of global expansion in anticipation of future development. We began business dealings with home appliance manufacturers and established a factory in Thailand after the one in Malaysia, where we also began business with automotive part manufacturers. After this, we continued to expand into China and the USA among other countries to expand our worldwide network. SANWA has continued to grow based on its reliably established technical capabilities through its consecutive use of new technologies. We will pass down our ambition for manufacturing to the next generation, an ambition that has remained unchanged since the company was first founded.

Staff working at the Malaysia factory (left is Vice-President Yoshihide Goto)

The Thailand factory as it is today

Washing machine and car panels for overseas

Aichi Quality Company Certificate

1994 |

Jun. |

|

|---|---|---|

| Sep. |

|

|

1995 The Great Hanshin Earthquake 1995 Tokyo subway sarin attack by Aum Shinrikyo |

||

1997 |

Aug. |

|

1997年 Japan’s consumption tax raised to 5% 1997 World’s first mass produced hybrid vehicle “Prius” released US 9/11 terrorist attacks |

||

2002 |

Jan. |

|

| Aug. |

|

|

2003 |

Aug. |

|

| Sep. |

|

|

| Dec. |

|

|

2004 |

Mar. |

|

| Apr. |

|

|

| Dec. |

|

|

2005 |

Jan. |

|

| May. |

|

|

| Jul. |

|

|

| Nov. |

|

|

2005 Chubu Centrair International Airport opens |

||

2007 |

Jul. |

|

| Oct. |

|

|

2008 Toyota Motor Corporation overtakes GM in global production 2008 Bankruptcy of Lehman Brothers |

||

2010 |

Apr. |

|

| Jul. |

|

|

2011 |

May |

|

2011 Great East Japan Earthquake |

||

2012 |

Feb. |

|

2014 |

Mar. |

|

| Aug. |

|

|

| Sep. |

|

|

2014 Japan’s consumption tax raised to 8% |

||

2015 |

Jun. |

|

2016 |

Jan. |

|

2017 |

Jan. |

|

2018 |

Jul. |

|

2019 |

Dec. |

|

2019 Japan’s consumption tax raised to 10% |

||

2020 |

April. |

|

2022 |

October. |

|

2023 |

October. |

|